rockwell hardness test lab report procedure|rockwell hardness test calculation : purchaser The Rockwell hardness scale is designed to determine the hardness of materials like aluminum, thin steel, lead, iron, titanium, copper alloys, and cemented carbides. This article explains the procedure to perform the Rockwell . webNas Profundezas do Mar Sem Fim, um filme de Ulu Grosbard. AdoroCinema. Ex.: Indiana Jones 5, Homem-Aranha: Através do Aranhaverso, Missão Impossível: Acerto de Contas Parte 1. Filmes

{plog:ftitle_list}

08/01/2024 - O projeto CONTRATAÇÃO DE DUAS EMBARCAÇÕES PARA A REALIZAÇÃO VI EXPEDIÇÃO CIENTÍFICA DO BAIXO SÃO FRANCISCO, A SE REALIZAR ENTRE OS DIAS 21 E 30 DE NOVEMBRO DE 2023 foi cadastrado. 08/01/2024 - O projeto CONTRATAÇÃO DE CONSULTOR PARA REALIZAÇÃO DE .

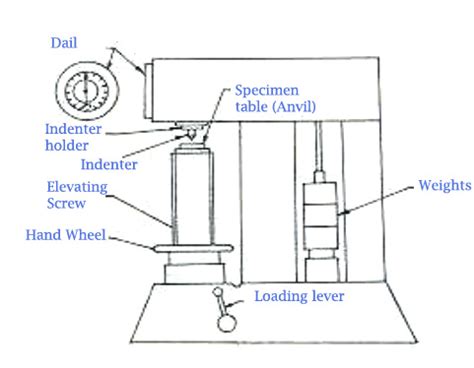

Rockwell hardness tester gives the direct reading of a hardness number on a dial provided with the machine. Specifications are as follows: Ability to determine the hardness up to 100 RHN. Maximum application of load 150 Kg. Minimum application of load 10 Kg. Method of load .1. ROCKWELL HARDNESS TEST 1. AIM: To determine the Rockwell Hardness of a given test specimen II. APPARATUS: Rockwell Hardness testing machine, Test specimen. III. THEORY: .The Rockwell hardness scale is designed to determine the hardness of materials like aluminum, thin steel, lead, iron, titanium, copper alloys, and cemented carbides. This article explains the procedure to perform the Rockwell .

The Rockwell hardness is derived from the measurement of the depth of the impression EP = Depth of penetration due to Minor load of 98.07 N. Ea = Increase in depth of .TableofContents ListofFigures ix ListofTables xii 1.Introduction 1 2.RockwellHardnessTest 2 2.1Significanceofthetest 2 2.2Rockwellindentationtestprinciple 2 2 . The purpose of this Guide is to explain the causes of variability in Rockwell hardness test results and to supplenment the information given in test method standards with .Rockwell hardness tester presents direct reading of hardness number on a dial provided with the machine. Principally this testing is similar to brinell hardness testing. It differs only in diameter and material of the indenter and the applied .

Rockwell hardness test. Use ASTM E 140-88 "Standard Hardness Conversion Tables for Metals (Relationship Between Brinell Hardness, Vickers Hardness, Rockwell Hardness, Rockwell .

rockwell hardness testing machine diagram

In Rockwell hardness test, a standard load (based on type of material) is applied through a standard indentor (cone or ball) for a specified duration, on the material & depth of impression . The Rockwell hardness test involves making an indentation on the test material. The indenter is either a conical diamond or a steel ball. Indenter ball diameters range from 1/16 to 1/2 inches and are chosen based on the test .1. Rockwell hardness test (scales A, B & C) methods : IS:1586-1988 Viva Questions: 1. What is Hardness? 2. What is the significance of minor load in Rockwell method of hardness testing 3. What are the advantages and limitations of Rockwell method of hardness testing 4. Where are Rockwell hardness test and Brinell hard test employed 5.The Rockwell hardness test method, as defined in ASTM E-18, is the most commonly used hardness test method. You should obtain a copy of this standard, read and understand the standard completely before attempting a .

The Rockwell hardness test continues to be applied as a tool for assessing the properites of a product while the tolerances on the acceptable material hardness have become tighter and tighter. Adhering to good practice procedures when performing Rockwell hardness measurements and calibrations is a beneficial step to reducing measurement errors.

rockwell hardness testing instructions

4) For Rockwell hardness testing, no optical measurements are required; all readings are direct. There are two common methods applied to measure material hardness macroscopically: Rockwell and Brinell. Rockwell hardness differs from Brinell hardness testing in that the indentation size is measured in BrinellSubject Title: Strength of Materials Course Title: B.Eng. Manufacturing Engineering Report Title: Hardness Testing Student Name: Unknown Fella upload this to help others Student Number: T00***** Assignment Date: 5/5/2020 Presented to: Gary Fort Declaration: I hereby declare that the work outlined above has been completed by myself, it has not been shared with any other .

View Lab - Lab report of Rockwell hardness test.docx from MTS 310 at National University of Sciences & Technology, Islamabad. Lab report of Rockwell hardness test By OBJECTIVES 1. To understand what

The Rockwell hardness test is widely used to standardize the hardness of metals. Do you know the Rockwell Hardness Test procedure? Read on to learn more about how to perform a Rockwell Hardness Test. + 86 755 61301520; [email protected]; Search. Home; About Us. Who We Are; Our History; ASTM E10: This standard covers Brinell hardness testing in metallic samples. ASTM E18: This standard includes the various ways that Rockwell hardness can be measured by standard methods, specifically for metallic materials. ASTM E384: This standard is for hardness testing on a micro-scale, and therefore includes the Vickers and Knoop hardness .

Hardness Test 1/5 LAB 2 HARDNESS TEST OBJECTIVES (1) Make Brinell, Vickers and Rockwell hardness measurements on different . The Vickers hardness test method consists of indenting the test material with a diamond indenter, in the form of a right pyramid with a square base and an angle of 136 degrees . ROCKWELL HARDNESS TEST The penetrators .Hardness testing within the realm of materials testing. Today, hardness testing is one of the most widely used methods in mechanical materials testing, especially for metals. On the one hand, this test method can be used to find qualitative relations to other material properties (e.g., strength, stiffness, density) or to the material behavior under certain stresses (e.g., abrasion . Variants on the Rockwell hardness test procedure are used depending on the material and strength of a part. The most common Rockwell variants include: HRC – Known as “Rockwell C,” a 150 kgf load is applied via a diamond in this method.

yield strength compression test

Rockwell testing falls into two categories: Regular Rockwell testing (e.g., C and B scales) and Rockwell superficial testing (e.g., 30 N and 30 T scales). High Rockwell hardness numbers represent hard materials and low numbers soft materials. d 2 www.wilsoninstruments.com Fundamentals of Rockwell Hardness Testing1. To perform a calibration of a Rockwell hardness tester using a standard test block; and . 2. To measure the Rockwell hardness of a steel reinforcing bar, a widely used construction material. (b) Learning Goals: 1. To be able to perform Rockwell hardness testing, a prominent technique

The Brinell Hardness Test method is the most commonly used hardness measurement technique in the industry. In the Brinell Hardness Testing, the hardness of a metal is determined by measuring the permanent indentation size produced by an indenter. . For the Rockwell Hardness Test, the Indenter is a Small Steel Ball (HRB) or a diamond cone (HRC .TableofContents ListofFigures ix ListofTables xii 1.Introduction 1 2.RockwellHardnessTest 2 2.1Significanceofthetest 2 2.2Rockwellindentationtestprinciple 2 2 .ATS Mechanical Testing experts perform Rockwell Hardness Tests in accordance with procedures designed for the results you need. . Rockwell Hardness testing is straightforward and uncomplicated in practice. Using a .

3.1 Macro Hardness Test Methods 3.1.1 Rockwell Hardness Test The Rockwell hardness test method consists of indenting the test material with a diamond cone or hardened steel ball indenter. The indenter is forced into the test material under a preliminary minor load 𝐹0 (Fig. 1A) usually 10 kgf. When equilibrium has been reached, anhardness measurements as a function of distance from the quenched end as obtained from the Jominy test. Module Procedure: 1. Discussion 1. When is hardness important? Hardness indicates resistance to deformation, so anytime a load is applied, hardness is important. When we think of hardness we usually think about a hammer or a knife, but resistanceWhat is Rockwell hardness testing? The Rockwell Hardness Test is generally a non-destructive test performed on samples when it’s necessary to determine how hard a material is. It’s generally considered easier to perform compared to other methods, like Vickers or Brinell hardness testing. Another advantage is the small area of indentation needed to carry out the . The laboratory report is about two experiments: Microstructure examination and Hardness test. I n hardness test three different specimens of high speed steel, mild steel and Aluminum was examined for

yield stress in compression testing

Rockwell Hardness TEST LAB Report. Course: Fundamentals of Materials Science and Engineering (MSE 301) 38 Documents. . testing method. The indenter is either a conical. diamond (brale) o r a hard steel ball. Different. indenter ball diameters from 1/16 to 1/2 in. are. used depending on the test sc ale.The Rockwell method is the most widely used on the American market. There are different reasons for this: Rockwell hardness testers are usually less costly than optical hardness testers, the test itself is quick and easy, surface finish of the material is not critical, and the Rockwell scale is a commonly accepted value when purchasing products.PDF | On Aug 27, 2023, Dokta Urame published EN113 Lab 02 Brinell Hardness Testing Report | Find, read and cite all the research you need on ResearchGateRockwell hardness test into what is today the most widely used method for acceptance testing and process control of metals and metal products. Since its development, the popularity of the Rockwell hardness test has steadily grown. The Rockwell hardness test continues to be applied as a tool for

This document describes procedures for harness testing of metallic materials using the Rockwell scale. The Rockwell hardness test measures the indentation made by specific loads on a material's surface. There are different Rockwell scales that use varying loads and indenters depending on the material. The experiment uses a Rockwell hardness tester with a diamond .EXPERIMENTAL PROCEDURE The specimen Al 2024 which was consist of 3.8-4.9% Cu, 1.2-1.8% Mg, 0.3-0.9% Mn, and Fe, Cr, Zn, Ti in a little amount had been. IPL > Rockwell Hardness Testing Lab Report Sample . Rockwell Hardness Testing Lab Report Sample; Rockwell Hardness Testing Lab Report Sample. 1123 Words 5 Pages.ISO 6508-1:2015, Metallic materials — Rockwell hardness test — Part 1: Test method ISO 6508-3:2015, Metallic materials — Rockwell hardness test — Part 3: Calibration of reference blocks 3 General conditions Before a Rockwell hardness testing machine is verified, the machine shall be checked to ensure that it is

rockwell hardness testing guide pdf

虎牙csboycs2重播,csboy与您分享cs2游戏乐趣。

rockwell hardness test lab report procedure|rockwell hardness test calculation